AlterEgo Stone

Stone

Modern natural stone cladding combines classic tradition with contemporary performance and buildability.

We offer a full portfolio of classic natural stone façades including limestone, sandstone and granite, all with high technical properties to suit the UK market’s specific requirements.

AlterEgo Façades systems enable the use of a natural stone in a contemporary and convenient format that is compatible with lighter building structures.

Selecting the correct stone is an important part of a project and the best way to avoid issues and unnecessary surprises when already on site.

We are always very transparent on where the material is sourced and actively encourage our clients to visit the quarries as part of the stone selection process to be able to fully understand this beautiful yet complex material. This typically includes a guided tour of a quarry and stone works where groups are shown how stone is formed and quarried and subsequently fabricated to desired specification.

While there the clients have the opportunity to learn more about natural stone, ask any relevant questions about the process, timescales and performance and see the material in greater scale rather than just samples prior to making any decisions.

All our quarries and manufacturing facilities are based in Europe, covered by CE marking and have relatively short lead in times for delivery to site.

Our natural stone rainscreen panels are sourced from key partnering quarries throughout Europe and can range from 30mm – 50mm thick depending on the properties of the stone selected and project specific requirements.

Importantly natural stone is non-combustible with an A1 rating.

Mechanical Kerf Fix:

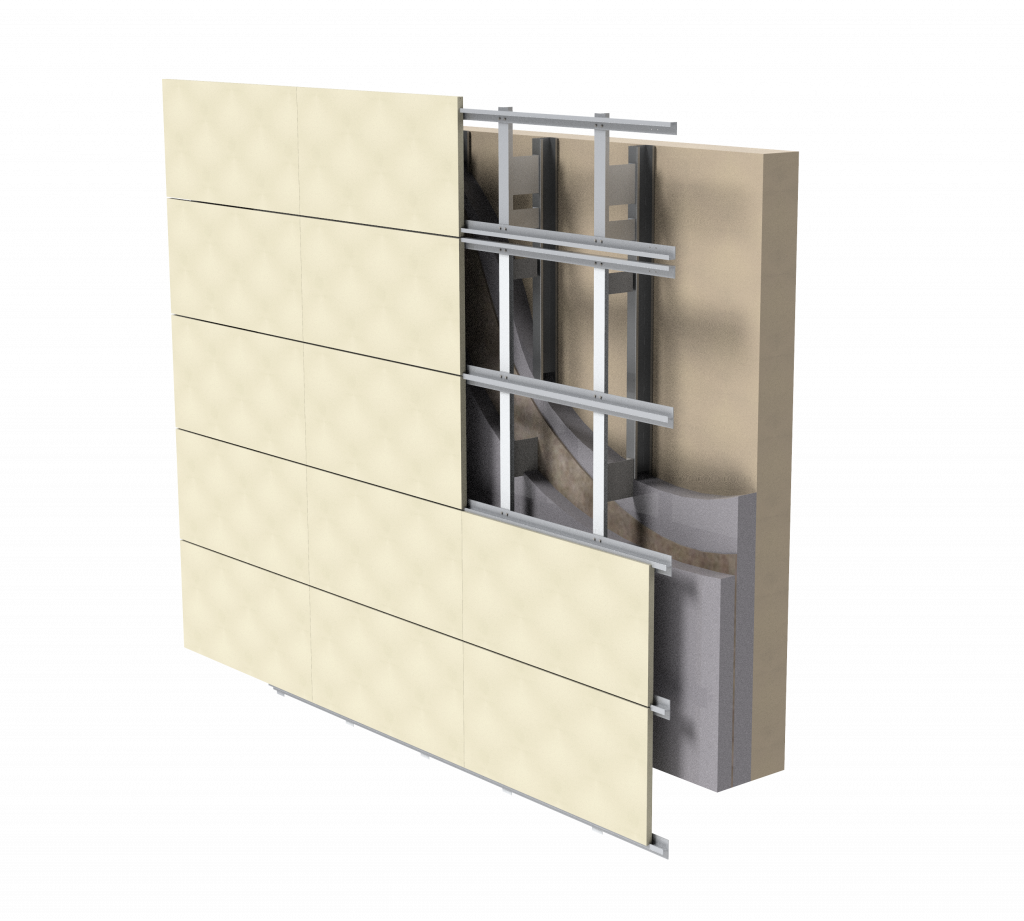

EGO-01H kerf system

The appropriate stone fixing system is dictated by the architects’ design intent for panel dimensions and layout combined with the flexural strength of a stone and project specific design wind loads. Our AlterEgo cladding systems are engineered, designed and manufactured in the UK and include mechanical kerf fix and secret undercut fix.

The kerf fix anchoring system is the most widely used stone cladding system and is ideal for natural stone panels with a thickness range from 30mm to 50mm. The system is suitable for both stack bond and stretcher bond facades and for complete design flexibility we have developed a hybrid solution allowing for combination of kerf and undercut anchor support for complex and large format façade designs.

Secret Undercut Fix:

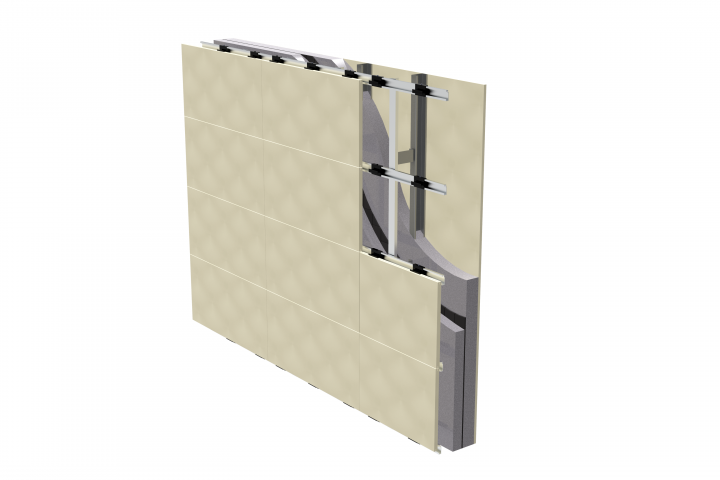

EGO-01H hanging clasp system

Depending on the stone panel dimensions and its orientation a concealed undercut anchor solution may be the most viable option and for this we have developed our hook on EGO-01H hanging clasp & horizontal rail system. The secret fix undercut anchor system is ideal for natural stone panels with a thickness range from 30mm to 50mm and is suitable for both stack bond and stretcher bond facades typically in portrait layout. The solution can cater for bespoke interface detailing and large format panels.

Mechanical Kerf Fix:

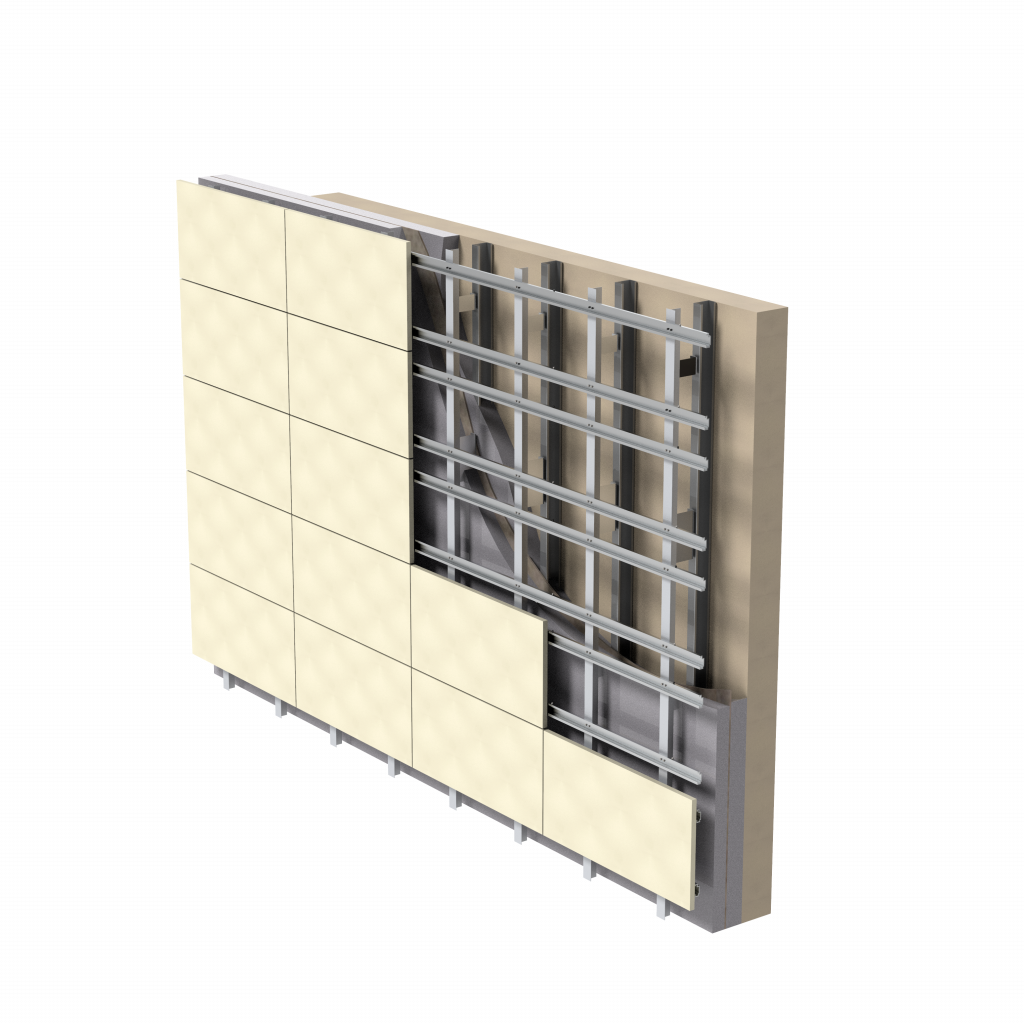

EGO-02 kerf system

The kerf fix anchoring system is the most widely used stone cladding system and is ideal for natural stone panels with a thickness range from 30mm to 50mm. The system is suitable for both stack bond and stretcher bond facades. It works especially well for mix bond and random stretcher bond layouts.