What is stone cladding?

Would seem a pretty simple question right? And yes, it’s a pretty simple answer – cladding made from stone. However from the meetings I have with contractors and surveyors, I see it often gets over-complicated in designers’ minds and confused with traditional stone masonry.

Natural stone is one of the oldest materials used by man in construction. We only have to look at buildings such as the Taj Mahal completed in 1648 using white marble, or the Great Pyramid thought to have been completed in 2560BC made predominantly out of limestone to appreciate the longevity of stone as a material. (Imagine the architect specifying the Design Life for the Pyramid….)

Construction methods have obviously changed since they built the Taj Mahal, and thanks to different sectors and trades within the construction industry cross-referencing and networking over the years, we no longer have to stack heavy stone blocks on top of one another to create the appearance of a solid stone building.

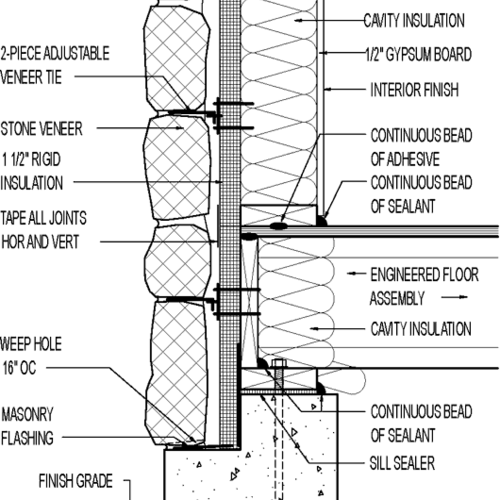

Traditional stone masonry (not something we do here at AlterEgo by the way), is loaded onto the building’s foundations and uses stones and mortar, tied back with wall-ties – think brickwork.

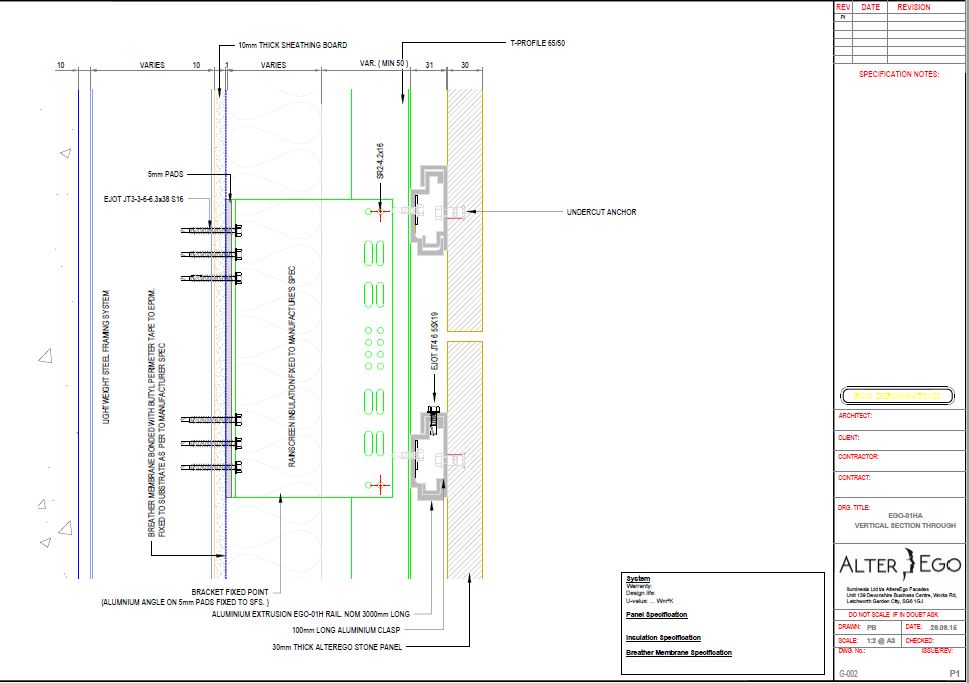

Modern day stone cladding on the other hand is hung from the building structure, and is put together much the same way as a metal rainscreen system is.

You see, stone cladding, is a rainscreen cladding system and should be treated as such.

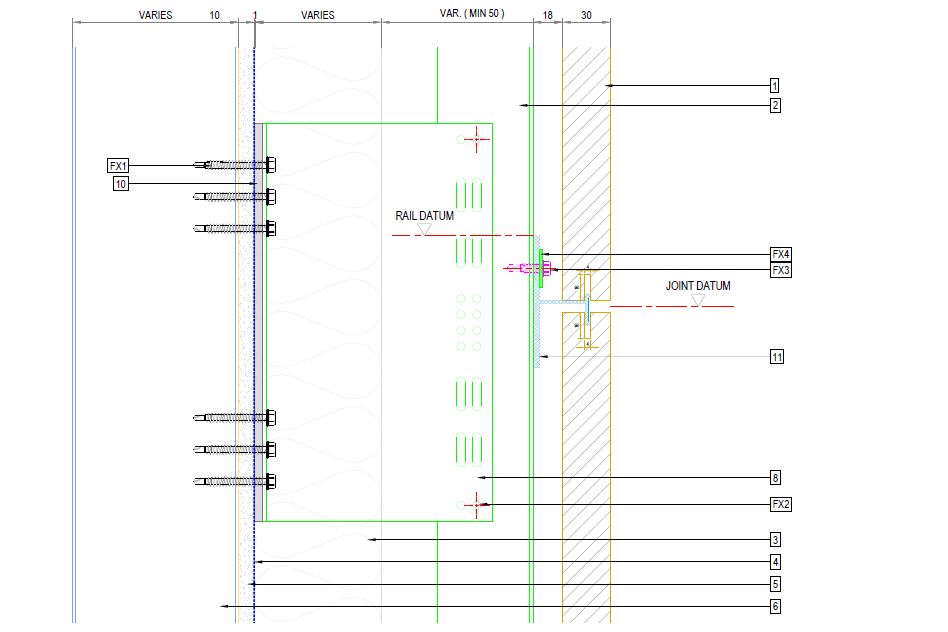

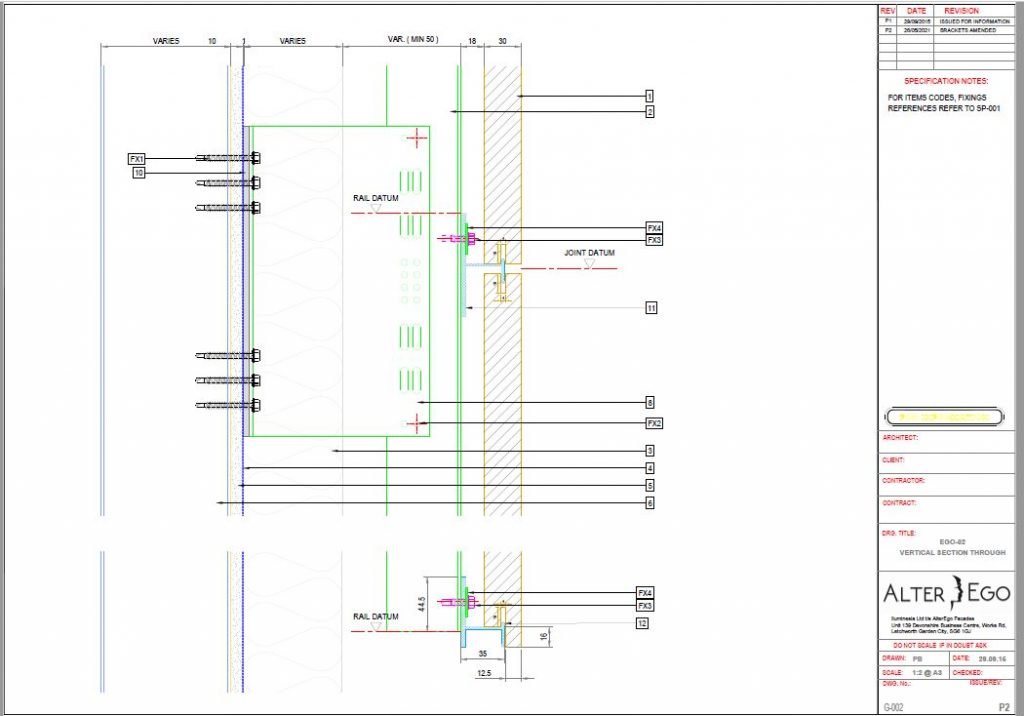

Looking through a cross section of a typical stone cladding build-up you’ll see lots of familiar components: spreader bars, helping-hand brackets, rails and T-bars. It’s only the facing material which is interchangeable.

There are a few nuances when working with natural stone for the first time, but nothing that a day’s training and our on-site support won’t cover.

So if you’re a contractor used to installing aluminium and steel cladding or you specialize in terracotta; don’t be afraid of stone! Check out this video showing the simplicity of our EGO-02S system EGO 02s INSTALLATION BETA – YouTube

When it comes to fixing the stone cladding panel to the support structure, there are two main fixing methods:

Undercut Anchors

With an undercut anchor system, typically used for larger format panels, holes are pre-drilled into the back of the stone, a sleeve and bolt inserted and fixed onto a hanging clasp and horizontal system. This method is good for natural stone panels with a thickness range from 30-50mm and can be used in both stack and stretcher bond layouts, typically in a portrait layout. Undercut anchors are always used in soffit situations.

As the fixings are all on the back of the panel, this method is completely secret-fix, no fixings are visible.

Kerf

The kerf method of fixing stone is where a continuous groove is cut in the top and bottom of the stone, and the stone simply sits on a rail or clasp at the bottom and restrained at the top. A kerf system works particularly well for horizontally laid panels in either stack or stretcher bond.

The speed and simplicity of installation and coupled with the fact that panels can be installed non-sequentially makes this method the most widely used stone cladding system.

Both installation methods are typically open-jointed, however pointing joints with a non-migratory sealant can give the appearance of a traditional masonry building.

If you’re considering stone for your next project, please get in contact.