In recent years stone started to re-appear more and more as a cladding material on projects in the UK. It is possibly due to the fact that stone (in its original form) is non-combustible in its nature and as we all know performance of cladding products in relation to fire has recently been the main focus of the industry. Naturally fire resistance of the product is important however there is the other side of the coin which is very often diminished by the industry and that is the structural integrity.

Providing a proof that the material and the system performs structurally on any given project should be on the top of any approval list. Naturally this can be done via a project specific testing at one of the UKAS accredited test centres, however, we noticed over the years that not every project has any allowance in their budget to carry out such testing. This omission very often leads to providing approvals to products based on what we call ‘generic testing’ typically carried out to CWCT standards for building envelopes which is absolutely fine for composites and materials that manifest constantly the same parameters . Stone is however the type of material that varies substantially in respect to its physical properties and as such has to be studied on project to project basis. This is also applicable in situation where even the same type of panel is used on different projects. In addition, relying merely on any performance testing does not determine the actual extent of the performance in case of a ‘pass’ scenario. Testing simplistically evaluates the product on a pass or fail basis. The issue is that testing does not state how close or far the panel was away from failing.

What we are trying to say here is that testing should be a secondary means of verification of performance and should be always following the structural analysis of the solution. In other words, testing should be a box ticking excerise when the performance of the solution is already known (at least in terms of cladding materials and not glazing systems).

It is fair to say that structural calculations are more detailed and more onerous than performance testing. The statement comes from a simple fact that testing utilised a safety factor of 1.5 of actual values (such as wind load and the performance of the panels is merely assumed) while a typical engineering analysis considers additionally factor of 3 on the LEV (Lowest Expected Value). Calculations in accordance with BS8298 utilised safety factor of 6 on a Mean Value. Using high safety factors covers for the natural aspect of the stone cladding panels. As we said before, any stone material will vary in terms of their physical properties from block to block, slab to slab and panel to panel. No two or three or 20 panels of cetrain material tested can be considered fully representative of the entire type of the material unless stone properties are tested every time a stone block is quarried, which is as we know not feasible.

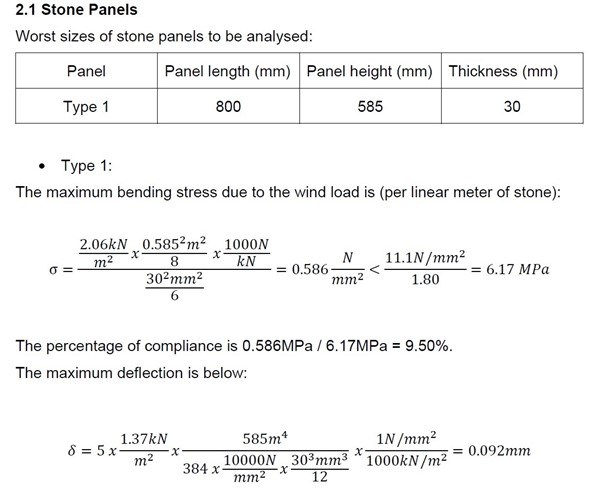

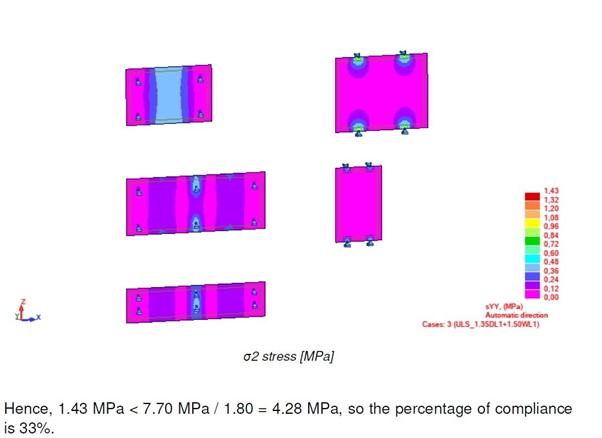

Structural calculations are the way to determine how well the panels will perform during the testing or on a project if no testing is carried out and pick up on potential issues with the solution. On the quick excerpts from our engineering analysis you will see how the resistance of the material vs the live loads can be determined, either by calculations themselves or via an MES study.

Even for most of us who are not trained engineers the performance of the panels is clearly represented in percentage of compliance.

Let us now imagine a panel/solution that was previously tested and installed on a project had a retrospective structural analysis carried out and the compliance was, say, 99% knowing that a 100% is a failure. Does it not make us think about a longevity of the solution (and bear in mind it may have passed some performance testing)? What would the clients do in such situation? Are all the projects verified in this manner and thus safe?

We will leave the questions open for your consideration and comments.